Abstract

An ideal drug delivery system should solubilize the drug, target to the specific site and should release the therapy for the effective treatment. Nano sponges are one of the novel drug delivery system which conquer the problems of drug toxicity and poor bioavailability as they can load both hydrophilic and hydrophobic drugs .Nanosponges have highly porous structure having the unique ability to entrap active moieties and offer a unique advantage of programmable release.Nanosponges can be prepared by cross linking different types of cyclodextrins with carbonyl or a dicarboxylate compound as cross linker.Nanosponges have a variety of application like enhancing the bioavailability of drug molecules and delivery of drugs into the oral,topical as well as parenteral routes. These can also be used as a carrier for biocatalyst in the delivery and release of enzymes, proteins,vaccines and antibodies.

Keywords

Nanosponges ,Cyclodextrins ,Biocatalyst

Introduction

Targeting drug delivery systems have been an ambition for a prolonged period in order to get the intented result. Nanosponge is a novel drug delivery system which conquer the problems of drug toxicity and poor bioavailability as they can load both hydrophilic and hydrophibic molecules[1]. Nanosponge is a nano sized material and is made up of tiny particles with a narrow cavity of few nanometers. These narrow cavities can be filled with various types of substances which can be both hydrophilic and lipophilic drug substance and thereby increases the stability of poorly water-soluble drug substance or molecules.[2] The nanosponges are a three-dimensional scaffold structure (backbone) or network of polyester that are capable of degrading naturally. Nanosponges are formed when these polyesters mixed with a crosslinker in a solution to form Nanosponges.These polyester breaks down in the body moderately as they are biodegradable .Once these scaffold of nanosponges breaks down in the body it releases the loaded drug molecules which in a controlled manner.

Advantages of nanosponges

- Enhance the aqueous solubility of the poorly water-soluble drug.

- Nanosponges can release the drug molecules in a controlled manner

- They act like a self sterilizer Because, bacteria cannot penetrate the nanosponges as they contain tiny pore structure to which the bacteria cannot enter.

- Nanosponges drug delivery system are non-irritating, non- mutagenic and non-toxic.

- Nanosponges help to remove the toxic and venom substance from the body.

- Reduced side effects

- Maximize formulation stability and enhance the flexibility of the formulation.

- Reduction in dosing frequency.

- Better patient compliance.

- They are stable over wide range of pH (i.e. 1- 11) and a temperature of 130 °C[3]

Disadvantages of nanosponges

- Nanosponges are only able to encapsulate small molecules, not suitable for larger molecules.

- Dose dumping may occur at times

Methods of preparation

- Solvent method

Nanosponges are prepared by combining polar aprotic solvents like Dimethyl sulfoxide (DMSO), Dimethylformamide (DMF) with the polymer. Then a crosslinker is added to this mixture in the ratio of 1:4. The above reaction is proceeded at temperature 10?C to reflux the temperature of the solvent for the time ranging from 1 to 48 hour. Once the reaction has been completed, the solution is cooled down at room temperature and then resultant product is added to bi-distilled water .After the product has been filtered under vacuum and refined by soxhlet extraction with ethanol followed by drying ,the product was recovered.

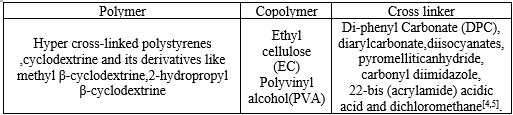

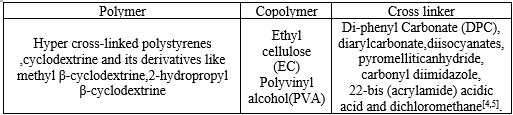

Materials used in the preparation of nanosponges

2.Ultra-sound assisted synthesis

Polymers and crosslinkers are made to react in a flask without the solvent. Then flask is placed in an ultrasound bath which is filled with water and heated up to 90?C .Tthen mixture is sonicated for 5 h and the mixture is cooled down to room temperature and the product is broken into rough pieces. The non-reacting polymer is removed by washing the product with water and refining is done using soxhlet apparatus (ethanol) to yield nanosponges.[6]

3.Emulsion solvent diffusion method

Different proportion or amount of ethyl cellulose and polyvinyl alcohol are used to prepare nanosponges in emulsion solvent diffusion method. Dispersed and continuous phases are used in this method. The dispersed phase containing ethyl cellulose and the drug, is then dissolved in 20 ml of dichloromethane and some amount of polyvinyl alcohol (PVA) as copolymer is added to 150 ml of the continuous phase (aqueous). The mixture is then stirred at the speed of 1000 rpm for about 2 h. The product obtained are filtered and collected. then the product concentrate is dried In an oven at a temperature of 400?C .

Loading of drug into nanosponges

To obtain nanosponges of particle size less than 500 nm, nanosponges should be pre-treated. So that the nanosponges are dissolved or suspended in water. The suspended nanosponges are vigorously sonicated to prevent the accumulation and centrifuged to produce a colloidal fraction. The supernatant is separated and the sample is dried using a freeze dryer. An aqueous suspension of nanosponges is made. for complexation an excess amount of drug is added to the suspension and continuously stirred for the certain period of time .After complexation completed the uncomplexed drug is removed from the complexed drug by using centrifugation. The solid crystals of the nanosponges are made by using a freeze dryer or by evaporating the solvent. This Solid Crystal structure of nanosponges play an important role in complexation of the drug. The drug loading capacities of para crystalline nanosponges is lower when compared to the crystalline nanosponges. The drug loading usually takes place as a mechanical mixture in weakly crystalline nanosponges[7]

Mechanism of drug release from nanosponges

The nanosponges have an open structure (since they do not have any continuous membrane in the surrounding of nanosponges), the active substance is addedin an encapsulated form to the vehicle. The encapsulated active substance can move freely from the particles into the vehicle until the vehicle gets saturated and the equilibrium is obtained. When the product is applied on to the skin, the vehicle containing the active ingredient gets unsaturated makin a disturbance in the equilibrium. Thus,the active substances flows from nanosponge particles into vehicles to epidermis until the vehicle is either absorbed or drie. The release of active substance continues to skin for a long period of time even after the retention of the nanosponge particles on the surface of skin i.e. the stratum corneum.

Factors influencing in the formulation of nanosponges

Nature of polymer

The polymer used in the preparation of nanosponges can influence its formation and performance. The size of the cavity of a nanosponge should be able to entrap a drug molecule of a particular size into it for complexation .

Drug

The drug molecules should have some specific characteristics to get complexed with the nanosponges:

- The molecular weight of the drug molecule should be in range of 100-400 Daltons.

- Structure of drug molecule should not consist of greater than 5 condensed ring.

- The solubility of the drug in water should be below 10 mg /ml

- The melting point of the drug should be below 250 0C

Temperature

Changes in the temperature can make an impact on the complexation of drug or nanosponges. Raising the temperature generally decreases the extent of the stability constant of the drug or the nanosponge complex which as a result of the reduction of interaction forces such as hydrophobic forces and Vander Waal forces of drug/nanosponges with a result of increase in the temperature.

Degree of substitution

The number, position, and type of the substituent of the parent molecule can affect the ability of complexation of the nanosponges greatly.

Method of preparation

The method of drug loading into the nanosponges can cause an impact in the complexation of drug and the nanosponges. Although, the success of a method mainly depends on the nature or the characteristics of the drug and polymer

Characterization of nanosponges

The characterization methods for the complexed drug/nanosponges are listed below:

Solubility studies

Inclusion complexes is a technique by which can determine the extent of solubility and bioavailability of the drug. This technique is the most widely used technique for analysis of the inclusion complexes of nanosponges. Degree of completion can be known by the plot of phase solubility. Solubility studies are conducted to assess the pH of the drug, solubilization outline and to identify the factors affecting drug solubility[8]

Microscopic study

Microscopic studies of nanosponges/drug can be conducted by using scanning electron microscop (SEM) and transmission electron microscope(TEM). Inclusion complex formation is indicated by the difference in the crystallization state and the product is evaluated under an electron microscope.

Zeta potential determination

Zeta potential is the difference of potential between two layers (dispersion medium and immobile layer) of fluid locked up with dispersed particles. Zeta potential is the major indicator for the stability of the colloidal dispersion. By placing extra electrode on particle size equipment or zeta seizer, the zeta potential can be measured. Higher the value of zeta potential of a colloidal dispersion higher is its stability.

Thermodynamical method

If any changes in drug molecules or particles takes place it can be determined by the thermo-chemical method. The changes of drug particles include melting, evaporation, oxidation and decomposition and polymeric changes. The changes in the drug molecules is as a result of the formation of a good complex

Particle size and polydispersity

Particles size is determined by the f dynamic light scattering using 90 Plus particle size determining software. Dynamic light scattering (DLS) is defined as a technique used to estimate the size distribution profile of nanoparticlesand thereby the final diameter of the particles and poly-dispersity index (PDI) can be found.

Thin layer chromatography (TLC)

TLC can be defined as method which can be used to separate the non-volatile or evaporative mixture. In this technique, if the Rf value of a particular drug molecule is of an acceptable range then it is useful l in recognizing the formation of a complex between drug and nanosponges

Infrared spectroscopy

The interaction between nanosponges and the drug in the solid state can be determined by using IR spectroscopy. Nanosponge bands can have slight changes during formation of complexes.. The technique cannot be used to identify the inclusion complex over the other methods

Loading efficiency

The loading efficiency of a nanosponge particle can be determined by the estimation of drug loaded into the nanosponge by the help of UV spectrophotometer and high-performance liquid chromatography method for the nanosponges.

Application of nanosponges

In the pharmaceutical industry, nanosponges can be used as an excipient for the formulation of tablets, capsules, granules, pallets, suspensions, solid dispersions and topical dosage forms. Nanosponges can entrap both lipophilic and hydrophilic drug molecules, basically, those drugs substances which comes under biopharmaceutical classification system (BCS-class II) as well as the poorly water-soluble drug[9]

Nanosponges for drug delivery

Nanosponges can carry the water-insoluble drug because of their tiny porous structure. Solubility and permeability of drug nanosponges complexes play a major role to increase the dissolution rate. It was shown that ?-cyclodextrine based nanosponges are three or five times more effective to deliver the drug to the targeted site. Nanosponges are generally solid in nature and can be used for oral, parental, topical and inhalation dosage form. For the preparation of tablet, capsule i.e. oral administration the nanosponges complexes should be dissolved in a suitable excipient like lubricants, diluents and anti-cracking agent. Nanosponges have properties that boost the product performance and elegance, controlled release, sustained release, decrease skin irritation, improve solubility and increase product flexibility.

Nanosponges for cancer therapy

Nowadays the most challenging works in the pharmaceutical field is the delivery of anticancer drug because of their low solubility The nanosponge’s complex load with a drug and expose a targeting peptide that fastens tightly with a radiation-induced cell upper layer on the tumor receptor. When nanosponges identify the tumor cell they stuck on the surface of tumor cel , start to release the drug molecules. The advantage of targeting drug delivery is to get a more effective therapeutic effect at the same dose and with minimal side Effect[10]

Nanosponges for delivery of protein

Bovine serum albumin (BSA) was used as a model protein to study the encapsulating capacity of ?-cyclodextrin-based nanosponges .Protein solution of bovine serum albumin (BSA) are stored in lyophilized form since it is not stable. Proteins can be denatured on lyophilization from its native structure. For the formulation and development of protein, the major concern is that to maintain its native structure and long-term storage during and after processing. For delivery of the protein like Bovine serum albumin (BSA) with the cyclodextrine based, nanosponges can increase the stability of these proteins. Nanosponges have also been used for immobilization of enzyme, encapsulation of protein, for controlled delivery and stabilization[11] .

Role of nanosponges for treatment of fungal infections

Fungal infections of the skin are one of the dangerous diseases in worldwide . Topical therapy is an attractive choice for the treatment of the coetaneous infections. Econazole nitrate (imidazole) is an antifungal or pharmaceutical fungicide used topically to cure athlete’s foot, ringworm, tineapityriasis versicolor, jock itch and vaginal thrush. Econazole nitrate is available t in the market as cream, ointment, lotion, and solution. Adsorption of econazole nitrate is significantly low when it is applied to the skin . So an effective therapy need a high concentration of active agents to be combined. For this purpose , econazole nitrate nanosponges were fabricated by emulsion solvent method.In this mehod econazole nitrate nanosponges were loaded in a hydrogel as a topical delivery for sustained release of the drug[12,13]

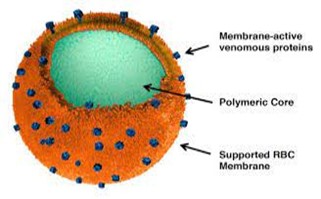

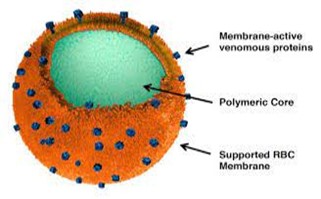

As absorbent in treating poison in blood

Nanosponges can be used to remove the dangerous poisonous substance from our blood by absorbing the poison. Incorporating the nanosponges by injection into blood nanosponges can soak up the toxins. In the bloodstream, the nanosponge looks like a red blood cell,which tricks toxins into attacking it, and then absorbs it. The number of toxin molecules each nanosponge can absorb depends on the type of toxin .

CONCLUSION

Nanosponges have been recognized as drug delivery system which can encapsulate or accumulate both hydrophilic and lipophilic drug by forming a complex. They can effectively deliver the drug in a controlled manner at the target site by reducing side effects.. Nanosponges can be incorporated into topical preparation like lotions, cream, ointments etc. And liquid or powder form also. The advantage of this technology offers targeting the drug to specific site reducing side effects, improving stability, and improving formulation flexibility and offering better patient compliance. Nanosponges also have application in other areas such as cosmetics, biomedicine, bioremediation process, agrochemistry,and catalysis etc.

REFERENCES

- Yadav GV, Panchory HP. Nanosponges–a boon to the targeted drug delivery system. J Drug Delivery Ther 2013;3:151-5

- Bolmal UB, Manvi FV, Rajkumar K, Palla SS, Paladugu A, Reddy KR. Recent advances in nanosponges as drug delivery system. Int J Pharm Sci Nanotechnol 2013;6:1934-44.

- Thakre AR, Gholse YN, Kasliwal RH. Nanosponges: a novel approach of drug delivery system. J Med Pharm Allied Sci 2016;78:103-11.

- Jilsha G, Viswanad V. Nanosponges: a novel approach of drug delivery system. Int J Pharm Sci Rev Res 2013;19:119-23.

- Shringirishi M, Prajapati SK, Mahor A, Alok S, Yadav P, Verma A. Nanosponges: a potential nanocarrier for novel drug delivery-a review. Asian Pacific J Trop Disease 2014;4:19-26

- Nanosponges: A New Approach for Drug Targetting K. Arshad Ahmed, Khan. Int J Pharm Pharm Res 2016;7:381-96.

- Sharma R, Pathak K. Nanosponges: Emerging drug delivery system. Pharma Stud; 2010. p. 33-5

- Trotta F, Zanetti M, Cavalli R. Cyclodextrin-based nanosponges as drug carriers. Beilstein J Org Chem 2012;8:2091–9.

- Trotta F, Dianzani C, Caldera F, Mognetti B, Cavalli R. The application of nanosponges to cancer drug delivery. Expert Opinion Drug Delivery 2014;11:931-41.

- Naga SJ, Nissankararao S, Bhimavarapu R, Sravanthi S, Vinusha K. Nanosponges: a versatile drug delivery system. Int J Pharm Life Sci 2013;4:2920-5.

- Güngör S, Erdal MS, Aksu B. New formulation strategies in topical antifungal therapy. J Cosmet Dermatol Sci Appl 2013;3:56

- Kaur G, Aggarwal G, Harikumar SL. Nanosponge: New colloidal drug delivery system for topical delivery. Indo Global J Pharm Sci 2015;5:53-7

- Renu Kadian. Nanoparticles: a promising drug delivery approach. Asian J Pharm Clin Res 2018;11:30-5.

- Bhowmik H, et al “ Nanosponges ; a review.”International journal of applied pharmaceutics, vol.10, no.4 ,May 2018

Hasna EK*

Hasna EK*

Junise V

Junise V

Farhana MK

Farhana MK

Shilpa KD

Shilpa KD

10.5281/zenodo.12739675

10.5281/zenodo.12739675